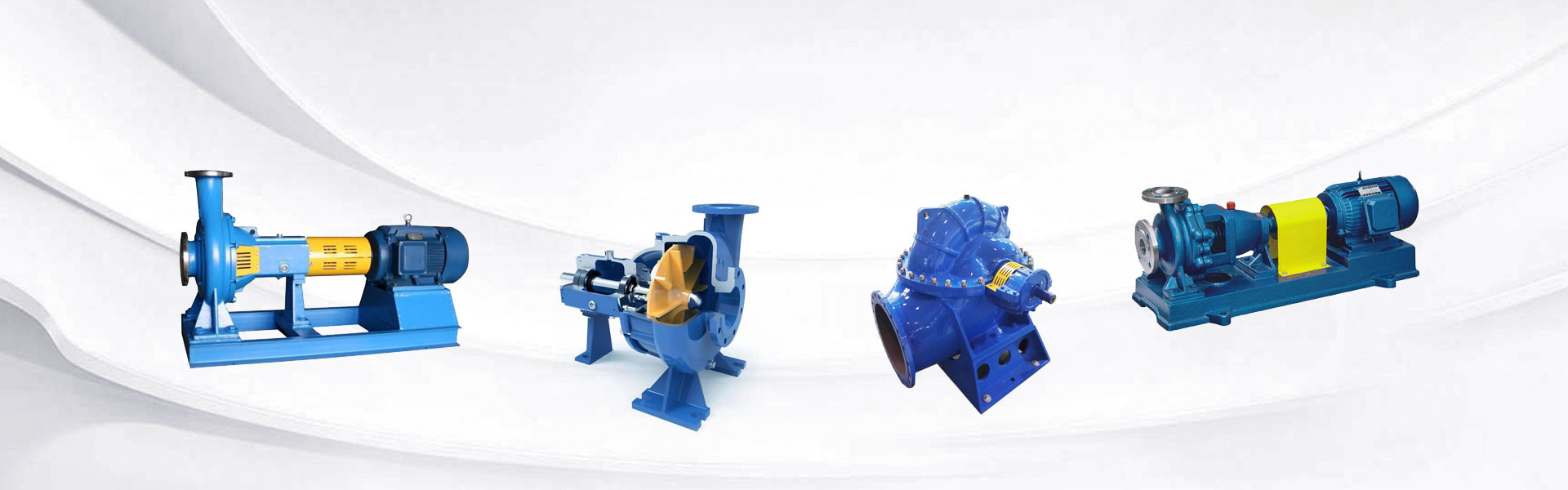

Hongzheng is Non-clogging Pulp Pump manufacturers and suppliers in China who can wholesale Non-clogging Pulp Pump. Non-clogging pulp pump is a new type of energy-saving pulp pump, which has the characteristics of high efficiency, no or less leakage, good anti-clogging, stable operation, high reliability, compact structure and so on. Mainly reflected in the following aspects: the use of semi-open or fully open impeller, wear-resistant plate and impeller front and side courtyard adjustable, shaft seal mainly uses mechanical seal and the selection of high-precision bearings (0 precision, and high-quality shaft materials, etc., so the non-clogging pulp pump is your ideal "good helper", while your success is also our pursuit.

Instructions for the use of non-clogging pulp pumps

1. Before starting the corrosion resistant pulp pump, it should be checked according to the following requirements.

1. Whether the bolts are fastened: whether thin oil has been injected into the bearing room (the oil level is the center of the oil mark).

2. Whether the coaxial degree of the coupling is less than or equal to 0.3mm, and the coupling should feel easy and uniform by hand

3. Motor steering is correct.

4. Whether the inlet valve is fully open.

5. Whether the outlet valve is closed.

6. Check whether the sealing water valve is open.

Sealing water pressure requirements for non-clogging pulp pumps:

1. Working pressure plus (0.3~0.5)kgf/cm

2. After starting the motor to the rated speed, slowly open the outlet valve to the rated working condition requirements (the motor running current is 80% of the rated value. Is appropriate).

3. During the operation of the pump, attention should be paid to the running stability of the pump and the cooling and flushing of the sealing water.

4. When the pump runs for a period of time or the head decreases, attention should be paid to adjusting the clearance between the front and side of the impeller. The adjustment method is as follows: First loosen the fastening nuts, turn the square adjustment screw (see the structure diagram) counterclockwise until the wear plate touches the front of the impeller, and then return the square adjustment screw to 112 turns clockwise. Finally control each nut tightly.

5. When the pump stops running, the outlet valve should be closed first, and then the motor power supply should be closed.

6. When the pump needs to be stopped for a period of time, the fluid in the pump should be drained for next use.

Hot Tags: Non-clogging Pulp Pump, China, Manufacturers, Suppliers, Wholesale, Factory, Brands, Cheap, Price, Quotation, Durable